#Hermann Brewery Equipment

Crafting Excellence, Brewing Success

Your Ultimate Beer Production Solution

LIFTED TO PERFECTION

DISCOVER OUR GUARANTEED USED BREWERY EQUIPMENT

500l brewery equipment

1000l brewery equipment

2000l brewery equipment

Hermann offers personalized turnkey solutions to customers

We customize equipment designs to match each customer's brewing method.

Customized Solutions

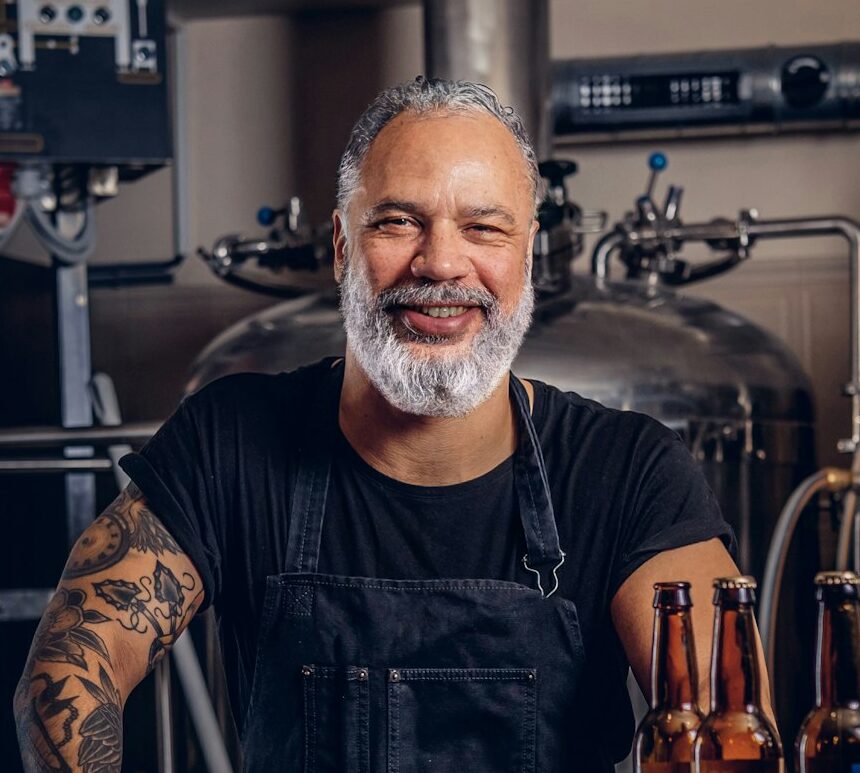

Why Hermann Brewery Equipment

Professional Brewery Equipment Manufacturer

GET UP CLOSE AND PERSONAL WITH OUR HIGH-QUALITY BREWERY EQUIPMENT

SEE TO BELIEVE

Bosnia 1000L brewing system

France 30T brewing system

Netherlands 300L brewing system

Malaysia 1000L brewing system

Mexico 500l brewing system

Singapore 1000L brewing system

UK 2000L Copper Brewing System

Finland 500L brewing system

Start-up microbreweries often choose brewery sizes of 10-30 barrels, with fermentation and bright tanks matching. For uncertain sales and growth, adjusting brewery size is wise. Alternatively, consider launching a nano brewery (1-10 barrels) for lower initial costs, scaling up as sales increase.

The primary factor influencing brewery equipment prices is the brewery’s capacity; larger capacities incur higher costs. Hermann offers a range from 1 to 80 barrels, with 1 barrel priced at approximately $20,000 (prices subject to market fluctuations; contact our engineers for precise figures). Larger capacities, ranging from $100,000 to $1,000,000, are available. While second-hand equipment is an option for budget constraints, Hermann’s prices remain competitive and comparable, making them a viable choice over used equipment.

Avoid using detergent for cleaning brewery equipment, as it can leave residues that damage the beer and affect its flavor. Common cleaners for brewery equipment include bleach and caustic solutions. Select cleaning agents based on the materials of the brewing equipment to ensure effective and safe cleaning processes.

In general, brewery components, primarily made of stainless steel, boast a lengthy service life. With proper maintenance and cautious chemical usage, brewery equipment can last 20-30 years. However, for filling and labeling machines featuring numerous moving parts, expect shorter service lives and increased maintenance needs. The specific durability of equipment varies based on its intended purpose within the brewery.

When planning a brewery, smaller setups ranging from 5BBL to 10BBL should account for a ceiling height of 12 to 15 feet in both the brewhouse and fermentation tank areas. Larger brewery equipment containers may necessitate additional ceiling height. Hermann offers customization for container sizes based on your specific requirements and conditions.

Starting a small business is already difficult, and craft breweries are highly capital-intensive businesses that require additional legal and licensing requirements. Starting a craft brewery requires not only a lot of planning but also money and patience. However, you can create your community brewery with sober planning, creative financing, and perseverance. If you need help, you can contact us and Hermann will provide you with the most complete turnkey solution.

We've completed the equipment installation and are now embarking on our inaugural brew. We sincerely appreciate your efforts in ensuring our equipment was installed smoothly. The tank design has turned out just as we discussed, and we're pleased with the outcome.

Everything is perfect with the brewery – easy to use, excellent extraction, efficient cooling, and well-calibrated. Brewing with it is a pleasure. It's simple to praise such a good product. I'm honest with everyone who visits the brewery; it's of very high quality.

We are very happy with the brewery you sold us, the brewers who saw it liked it, and asked us where they made them, cheers.

Contact Us For The Brewery Equipment Price

- We will contact you within 12 hours

- Don't worry, we hate spam too!